UV Printing Explained: Gloss/Varnish & Primer | JPPlus

Learn the difference between gloss, varnish, and primer in UV printing. Discover how each enhances adhesion, durability, and design with Johnson Plastics Plus.

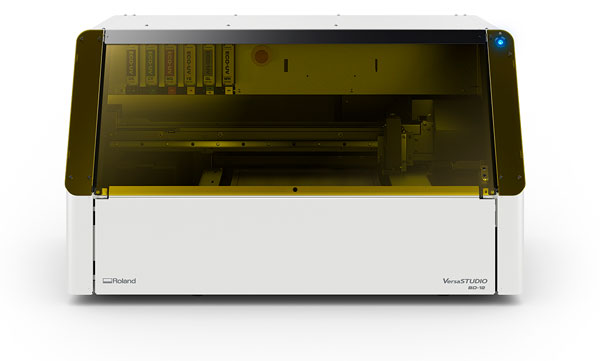

As trusted brands like Roland and Epson introduce affordable, compact UV-LED printers, the technology is becoming more accessible than ever. Combined with the capability to print full-color designs instantly on a variety of surfaces such as wood, metal, leather and more, it’s no surprise UV-LED printing is growing in popularity. In addition to instant full-color prints, UV printers offer the option for various ink types including: primer and gloss/varnish. In this blog, we’ll break down what each ink type is, what they’re used for, and some application ideas for getting the most out of your UV printer.

What is Gloss in UV Printing?

Gloss ink in UV printing adds a shiny, polished finish to your printed design. Gloss ink, also referred to as varnish, is a clear layer of ink added to your design to add extra dimension and shine.

Key benefits of gloss in UV printing:

• Gloss ink enhances the color and vibrancy of UV prints

• UV gloss adds a professional, high-end shine to logos, text, and graphics

• Gloss can be applied selectively for spot gloss UV printing, creating contrast against matte areas

• Enhances the tactile experience perfect for packaging, business cards, or signage

• Use gloss when you want your design to stand out visually and physically

What is Varnish in UV Printing?

Varnish and gloss are used interchangeably when referring to types of UV ink. Varnish, or gloss, ink adds a shiny polished finished to your printed design.

What is Primer in UV Printing?

Primer inks aren’t quite as ‘sexy’ as gloss or varnish, but are a seriously great tool for UV printing. Primers help with promoting adhesion to certain materials, like glass, metal, or acrylic, that are traditionally difficult for UV inks to bond with. Most printers that utilize primer do so through actually printing the primer through the print head. In other words, applying the primer is almost always part of the printing process. Applied before printing the white and color ink layers, primer ensures that the ink properly adheres to non-porous or slick substrates.

Key benefits of primer in UV printing:

• Promotes strong ink adhesion on challenging surfaces.

• Expands your selection of substrates.

• Reduces risk of peeling, chipping, or flaking over time.

• Essential for high-value items like drinkware, electronics, or coated metals.

• Use primer whenever you’re printing on slick, smooth, or unusual surfaces where adhesion is critical.

• Increases print durability for items or surfaces that are handled often.

• Replaces the need to apply UV adhesion promoters.

Gloss/Varnish vs. Primer: When to Use Each

Here’s a quick breakdown to help you decide:

• Gloss/Varnish – Best for enhancing visual appeal and creating a polished, eye-catching finish.

• Primer – Necessary for adhesion when working with non-porous or difficult substrates.

It’s important to note that when using gloss inks or varnish, you may need to employ an adhesion promoter to help the gloss inks stick to your substrate.

Why UV Printing with Gloss/Varnish, and Primer Matters for Your Business

Understanding these UV printing features can give your business a competitive edge. Adding gloss or varnish can increase the perceived value of your product, while primer ensures durability and longevity. At JPPlus, we carry a full line of UV printers, UV printing supplies, and blank products ready for customization. Our team of experts can help you find the right materials and techniques to bring your creative ideas to life.

Project Ideas for Primer and Varnish UV Inks

Creative Applications for Primer and Varnish in UV Printing

Varnish ink applications in UV printing opens up a world of creative possibilities, allowing designers to add unique finishes and enhance the visual appeal of their products. Here are some innovative applications for using varnish inks:

• Spot Finishing: Use varnish selectively to highlight specific areas of your design. This technique is perfect for creating contrast and drawing attention to key elements like logos, text, or intricate graphics. Spot varnish can give a tactile dimension to packaging, invitations, or business cards. For example, you can use varnish on a sports image and highlight the number on a jersey.

• Textured Effects: Varnish can be used to create textured patterns that are both visually and physically engaging. By layering varnish, you can simulate the feel of embossed or raised surfaces, adding a luxurious touch to items like book covers or premium marketing materials. For example, you can create a cheetah-print that features a tactile feel by layering parts of the pattern with gloss/varnish!

• Enhanced Durability: Beyond aesthetics, varnish also provides a protective layer that can increase the longevity of prints. This is particularly beneficial for items that are frequently handled or exposed to environmental elements, such as outdoor signage or promotional materials.

• Custom Finishes: Experiment with different varnish finishes, such as matte, satin, or high-gloss, to tailor the look and feel of your products. This versatility allows you to align the finish with the brand’s identity or the desired customer experience.

Interactive Designs: By incorporating varnish into your printed designs, you can create interactive elements that change appearance under different lighting or viewing angles. This dynamic effect can captivate audiences, making your products memorable and engaging.

• Artistic Creations: For artists and designers, varnish offers a medium to explore creative expression. Use it to add depth and dimension to artworks, prints, or bespoke creations, turning simple prints into gallery-worthy pieces.

By leveraging the unique properties of varnish inks, you can elevate your UV printing projects, adding both functional and decorative value to your creations. Whether you're aiming for a subtle enhancement or a bold statement, varnish inks provide the tools you need to make your designs stand out.

Primer ink applications in UV printing offer numerous possibilities to maximize ink adhesion on challenging surfaces while expanding the range of usable materials. Here are some creative applications for primer inks:

• Printing on Glass and Metal: Using a primer is crucial when printing on non-porous surfaces like glass and metal. It ensures that the UV ink adheres firmly, reducing the risk of chipping or peeling, and preserving the integrity of your design in the long term.

• Customized Projects on Plastics and Acrylics: Smooth materials such as glossy plastic or acrylic often pose adhesion challenges. Applying a primer before printing creates a receptive surface, ideal for customizing promotional items, display panels, or other plastic products.

Explore UV Printing Solutions

Ready to take your UV printing projects to the next level? Browse our selection of:

Frequently Asked Questions About Gloss, Varnish, and Primer in UV Printing

Do I need primer for UV printing on metal or glass?

Yes. Primer is essential when printing on slick or non-porous surfaces like glass, metal, and certain plastics. It ensures strong adhesion, preventing chipping or peeling over time.

Is varnish the same as clear coat in UV printing?

In many cases, yes. While clear coats and UV varnish are chemically different, UV varnish can serve a similar purpose as what a traditional clear coat would be used for. UV varnish works as a clear coat to protect designs while adding different finish options. Unlike traditional coatings, UV varnish is cured instantly with UV light for durability.

What materials benefit most from primer in UV printing?

Primer is especially useful for glassware, coated metals, ceramics, acrylic, and glossy plastics. Primer is useful with any material where UV ink adhesion is typically challenging.