RELIABLE INDUSTRIAL

LABELING MATERIALS

Fast lead times, consistent stock, and compliant with UL 969, NFPA 70, and ADA standards. Durable, easy-to-fabricate plastic sheets in the colors you need, designed for precision engraving and printing. Streamline your projects with customizable options and flexible order volumes for every need, including data centers, signage, and specialized applications.

Talk to an industrial labeling expertSHOP LABEL/TAG MAKING EQUIPMENT

COMPARE OUR TOP SELLING MATERIAL

| Material | LaserMax® | UltraGrave® | Textures | Durmark | Mattes | Satin | Safe-T-Mark |

|---|---|---|---|---|---|---|---|

| USAGE | Asset tags, equipment tags, warning labels, solar tags, & valve tags | Asset tags, equipment tags, warning labels, solar tags, & valve tags | Equipment tags, warning labels, control panels, and tags | Asset tags, control panels, equipment labels, switch tags and solar tags | Signage, equipment tags, safety signage, control panels, and tags | Warning labels, equipment tags, control panels, and tags | Equipment tags, warning labels, control panels, and tags |

| MATERIAL | Microsurfaced Impact Acrylic | Microsurfaced Impact Acrylic | Co-extruded Impact Acrylic | Impact Acrylic | Microsurfaced ABS | Acrylic cap/ ABS core | Fire Retardant Functional Polymer |

| FABRICATION METHOD | Laser engraving, rotary engraving & UV printing | Laser engraving & rotary engraving | Laser engraving & rotary engraving | Laser engraving, rotary engraving & UV printing | Laser engraving, rotary engraving & UV printing | Rotary engraving | Rotary engraving |

| UV STABLE | |||||||

| FIRE RETARDANT* |

|

||||||

| INTERIOR USAGE | |||||||

| EXTERIOR USAGE | |||||||

| UL CERTIFIED |

If your next project requires a custom solution,

Our team of experts can help!

From unique color combination to custom sheet sizes, we work directly with the industry’s leading plastics manufacturers to get you the exact material you need to help your customer.

Learn more about custom optionsRESOURCES

Learn more about the materials we offer for industrial tags.

VIEW ALL VIDEOS VIEW ALL BLOGSIndustrial labeling refers to the durable tags, signs, and markings that identify and organize components in demanding environments, from manufacturing floors to data centers. Specific electrical tags, labels, and identification products industrial labeling applications include pipe and valve tags, safety and compliance signage, control panel overlays, electrical switch plates, equipment asset tags, and data center cable identification.

Whether you're creating fast cable labeling systems for technicians who need to make tags on demand, labeling electrical panels in an industrial plant, or managing thousands of cables in a server room, Johnson Plastics Plus offers materials designed for clarity, durability, and performance in any environment.

Labeling and Tagging Considerations

1. Environment (Indoor vs. Outdoor)

Determine whether the labels will be used in an interior or exterior setting. For outdoor environments, UV-stable and outdoor weatherable engravable plastics ensure long-lasting readability. For indoor data centers and electrical rooms, low-glare, flame-retardant plastics are ideal to minimize reflection under LED lighting.

2. Application Type

The right material for a light switch plate differs from what's needed for a high-temperature equipment tag. For datacom labeling, flexible plastics or adhesive-backed materials are preferred for smooth mounting on cable trays, racks, and patch panels.

3. Exposure to Chemicals or Heat

In manufacturing, exposure to cleaning solutions or chemical vapors may require chemical-resistant and fire-retardant materials. In data centers, static dissipation and flame resistance are crucial for safety compliance. Rowmark's Durmark, Safe-T-Mark, and LaserMax® product lines are engineered to meet these needs.

Uses and Applications

Industrial and data center labeling systems serve a broad range of industries, including manufacturing, automation, electrical, and datacom infrastructure.

• Control Panels & Switchgear

Identify relays, switches, and circuit functions using non-conductive phenolic plastics or Safe-T-Mark engravable sheets. These durable materials ensure legibility while maintaining electrical safety.

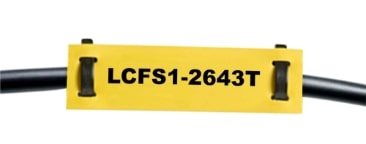

• Data Center & Datacom Labels

Properly identifying cables, racks, and ports is essential for efficiency and troubleshooting. Use laser-engraved or printed tags for fiber, copper, and power cabling to maintain compliance with TIA-606-B labeling standards.

• Equipment & Asset Tags

Track preventative maintenance and asset inventory using engraved or printed barcode and QR code labels. Laserable plastics deliver crisp, high-contrast results ideal for serial numbers and unique identifiers.

• Safety & Compliance Signage

From “High Voltage” to “Authorized Personnel Only,” engraved or printed industrial signage communicates safety protocols clearly. Choose high-contrast plastics or metal plates for long-term visibility.

Recommended Materials

JPPlus offers a full range of engraving and marking materials ideal for industrial and datacom labeling applications. Our diverse offering of materials includes a broad range of colors, materials, and thicknesses of compliant industrial labeling materials for safety, regulatory, and facility signage.

Engravable Plastics

Our engravable plastics are an ideal material for data centers label cables for long-term durability and readability. Two-layer engravable plastics from Rowmark and IPI are durable, easy to fabricate, and available in a wide range of color combinations. Options include:

• UV-stable and weatherable materials for outdoor durability

•

Flame-retardant, chemical-resistant engraving sheets for industrial and electrical use

Engravable Metals

For heavy-duty identification, choose stainless steel, aluminum, or brass. Combine rotary engraving or laser marking with CerMark metal marking spray for lasting results in high-traffic or harsh environments.

Data Cable Printers

When it comes to on-site cable tag production tools for data center technicians working in data center and datacom labeling, precision and consistency are key. The CAB EOS 2 cable printer is a top choice for on-site cable tag production tools for data center technicians because it delivers high-quality, durable identification for cables, patch panels, racks, and components. Compact yet powerful, it's designed for efficient production of heat-shrink sleeves, wrap-around labels, and self-laminating markers used in structured cabling and electrical identification.

Engineered to be the best equipment for creating cable labels during live installations, the CAB EOS 2 ensures every label is clear, legible, and compliant with TIA-606-B standards, making it an excellent choice for IT installers, industrial technicians, and network infrastructure specialists.

Frequently Asked Questions (FAQ)

What's the best material for labeling cables and racks in a data center?

Laserable engravable plastics, like LaserMax or DurMark, or durable printed polyester labels work best. They resist heat, static, and abrasion while meeting TIA-606-B labeling standards for datacom systems.

Can engravable plastics be used outdoors?

Yes. Many JPPlus engravable plastics, like Rowmark's LaserMax Outdoor line, are UV-stable, weather-resistant, making them ideal for exterior use. It's simple to create some of the best industrial tag for long-lasting cable labels in data centers with these tough, tested, and durable plastics.

What's the difference between metal and plastic labels for industrial applications?

Metal labels are preferred for high-temperature or heavy-wear environments, while engravable plastics offer lighter weight and cost-effective durability for indoor or electrical panel use.