SHOP PRINTERS AND SUPPLIES

GETTING STARTED

DIRECT-TO-GARMENT PRINTING

Direct-to-garment, or DTG, printing is an exciting technology that works well for printing on soft substrates and fabric materials, like t-shirts, tote bags, and more! The DTG technology works by laying down ink, directly onto a pre-treated fabric. DTG technology prints white ink allowing you to create full color, vibrant prints with a soft hand.

The Epson SureColor F1070 is a versatile printer designed for both Direct-to-Garment (DTG) and Direct-to-Film (DTF) printing. Compactly built with a 28” design, the SureColor F1070 fits perfectly into smaller shops, home offices, workshops, and confined spaces, making it ideal for individuals or businesses producing 100-200 t-shirt prints per month. The printer’s max platen size of 10” x 12” enhances its versatility for garment printing.

HOW DOES IT WORK?

PRETREAT

Apply pretreat to your garment to create an optimal printing surface.

PRE-PRESS GARMENT

Pre-pressing the garment cures the pretreat and provides a smooth surface for the ink to adhere.

PRINT ON GARMENT

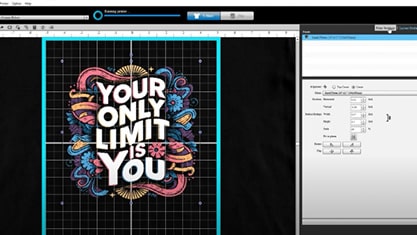

Place your garment in your direct-to-garment printer and print your design.

PRESS GARMENT

The garment is heat pressed using parchment paper to cure the ink and promote design durability.

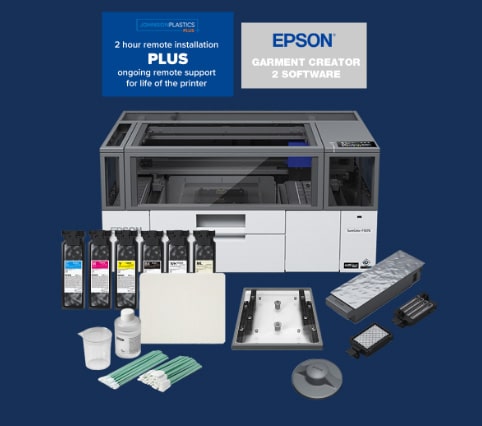

EPSON F1070 BUNDLE OPTIONS

Designed to help you do more and save more!

EPSON F1070 BUSINESS EDITION BUNDLE OPTIONS

DIRECT-TO-GARMENT RESOURCES

Our team of experienced professionals are ready to help you every step of the way. From installation to production, we make sure you get the most out of your direct-to-garment printing experience. Our friendly service team provides free, expert installation guidance and helps make suggestions as to the right materials and supplies to give you the best results possible!

BUILD YOUR DREAM BUSINESS!

Talk to one of our trained experts to make sure you get the right right equipment for your business! From printers to heat presses and everything in between, we’ll take the mystery and uncertainty out of the buying process and set you up for success!

CONTACT USLet our team of experts be your trusted source for direct-to-garment equipment!

When you purchase your equipment through JPPlus, you'll not only get FREE lifetime tech support but also FREE remote installation.

Our friendly team of equipment experts will help get you up and running and help troubleshoot any issues that may come up.

CONTACT SUPPORT TEAMShop DTG Printers & Supplies for Custom Apparel Printing

Create full-color, custom prints on any color fabric with a direct-to-garment printer. Whether your customers want a customized black cotton t-shirt or a hot pink tote bag with a custom logo, a DTG printer can make it a reality.

Avoid the mess and minimums required for some garment printing technologies, and start saying yes to more custom apparel print jobs with your DTG printer! With equipment bundles and industry-leading brands, Johnson Plastics Plus is the best place to start your DTG custom apparel business.

What is DTG printing?

Direct-to-garment, or DTG, printing is a process for printing full-color images directly onto fabric products. The process requires a specialized DTG printer, inks, pre-treated garment, and a heat press.

Is DTG printing durable?

Yes! DTG printing results in durable, full-color prints. When you print directly onto your pre-treated fabric, the specific DTG ink sticks to your substrate and is sealed in with a final press. If you require an even more durable print, we recommend looking into direct-to-film (DTF) printing, or utilizing the DTF hybrid feature on the Epson SureColor F1070.

How does DTG printing work?

DTG printing works by using a specialized printer to apply water-based inks directly onto pre-treated fabric. To start, you’ll need a pre-treated garment. This garment can be purchased pre-treated, or you can use a pre-treatment solution. This pre-treatment process is what helps the ink bond effectively to the fibers in your garment. While pre-treatment is not required for the process of DTG to work, we recommend it for the best adhesion results.

After pre-treatment, place your garment onto the printer platen and the printer then applies the ink directly onto the garment in a single pass, using precision nozzles to create vibrant, full-color images. After printing, the garment is cured with heat using a heat press, which ensures the ink is set and the print is durable.

What fabric is best for DTG printing?

Direct-to-garment (DTG) printing is a popular printing technology because of its versatility. Pre-treated shirts, like RTP shirts, work best or you can treat your own shirts using a pre-treatment system. It’s best to avoid using performance fabrics with DTG. For performance fabrics, you’ll achieve better results with DTF prints.

DTG printing setup guide

When you purchase a DTG printer with JPPlus, we help simplify the setup process! Simply schedule time with our customer success team, and they’ll walk you through step-by-step how to get your DTG printing equipment installed and printing.

DTG vs DTF Printing

DTG and DTF are two distinct printing technologies for printing on soft-goods. Direct-to-Garment (DTG) printing lays ink down on a pre-treated material. Direct-to-Film prints ink onto a film, which is then transferred onto the fabric using a heat press. The DTF method allows businesses to print on a wider range of materials, including those that might not be ideal for DTG printing, such as performance fabrics. While both DTG and DTF are durable prints, DTF offers a slightly more durable option.

DTG and DTF are both ideal technologies for businesses looking to expand their custom apparel offerings, and the Epson SureColor F1070 is a perfect choice due to its DTF/DTG hybrid capabilities!