Direct-to-Garment (DTG) Printing Buyer's Guide

Direct-to-Garment (DTG) printing allows print shops and creative entrepreneurs to print full-color images, directly onto cotton garments and fabrics with the push of a button. DTG printing produces full color images with a soft hand feel without need for messy screen printing, tedious weeding, or a complex transfer process. This guide breaks down our favorite DTG equipment solutions to help you find the best fit for your production volume, garment types, and business goals.

Who Should Read This Guide?

This guide is ideal for:

• Garment decorators who want detailed, photo-quality prints on cotton and natural fabrics

• Print shops offering short-run (10-100) or on-demand t-shirt printing

• Entrepreneurs looking to start a custom apparel brand

• Businesses looking to complement their current heat transfer or sublimation technologies

• Creators needing quick-turn, full-color prints with a soft finish

What is DTG Printing?

Direct to Garment (DTG) printing applies ink directly onto a pre-treated fabric and that ink is absorbed by the fabric fibers. It produces vibrant, high-resolution, full-color designs, perfect for cotton garments and blends, the images are soft to the touch and resist cracking.

The fabric for DTG has a special pre-treatment applied that allows the ink and pigment to stick to the garment. This pre-treatment can be applied manually using a pre-treat machine or you can purchase pre-treated blanks, like RTP shirts.

Pretreat must always be used when printing with white ink, but can also be used for brighter colors and longer lasting prints when white ink isn't being utilized. DTF (Direct to Film) is a great alternative, when you are working with fabrics that are not compatible with DTG ink, since it can be applied to a wide range of materials.

DTG is an ideal technology for business owners who want the capability to sell on-demand, small batch, and custom print jobs. It offers a soft-hand feel, crisp detail, and fast turnaround. With the right pre-treatment (when necessary) and curing process, prints are durable and long-lasting.

What do you need for DTG printing?

DTG printing requires a special direct-to-garment printer, a pre-treated garment (when using white ink), a heat press, and a finishing sheet for your final press. Check out this video for the full process:

Essential DTG Accessories & Supplies

For optimal print quality and performance, pair your DTG printer with these must-have accessories:

DTG Pre-Treatment Equipment & Supplies

• Pre-Treated Garments - You can pretreat yourself or purchase pre-treated.

• Pre-Treatment Solution - Ensures white ink adhesion and wash durability.

• Pre-Treat Machines or Spray Guns - If you’re treating your own garments, these systems allow for even application for dark garments.

• Heat Press or Tunnel Dryer - Cures ink and pre-treatment properly.

• Garment Holders & Platens - Stabilize shirts for clean printing (often supplied with your machine or you can buy interchangeable platens)

• Cleaning Kits - Maintain nozzles and lines for consistent results

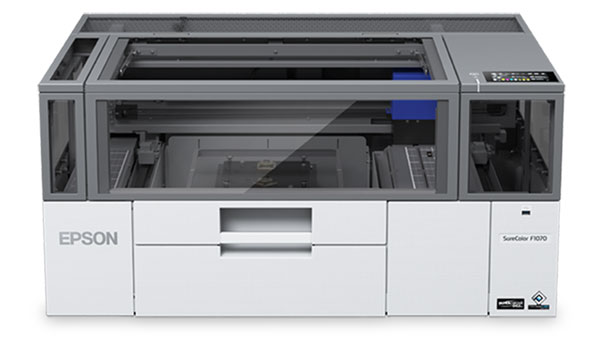

Epson SureColor F1070 DTG/DTF Hybrid Printer

The Epson SureColor F1070 is our preferred DTG printer. The Epson SureColor F1070 is an affordable machine, both in terms of shop-space and your budget. Plus, with the hybrid DTF transfer film capability, it allows printing on a wide variety of materials, including uniquely shaped items and gives you two machines in one. Along with Epson’s trusted name, you’ll receive a PrecisionCore Micro TFP printhead with Nozzle Verification Technology and next-gen UltraChrome DG2 Ink, for vibrant, clear, and detailed prints.

Features:

• Maximum platen size 10" x 12"

• Compact 28" design for small spaces

• Hybrid DTG & DTF capabilities for various fabrics and shapes

• Touchscreen Interface

• PrecisionCore Micro TFP printhead with up to 2,400 dpi and Nozzle Verification Technology

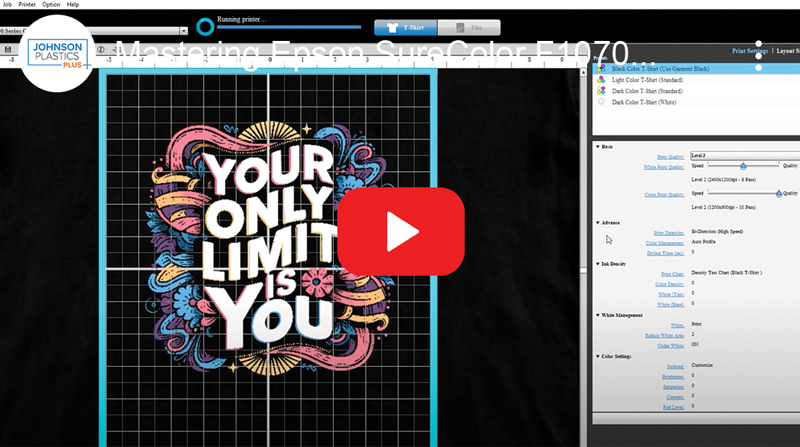

• Epson Garment Creator 2 software for fast, high-res processing

• Epson Cloud Solution PORT®1 — provides live production monitoring, reporting and job cost accounting

• Versatile fabric handling up to 1" thick

Applications:

• T-Shirts - 100-200 vibrant prints per month

• Apparel - Print on hoodies, bags, and more

• DTF - Transfer prints for polyester, leather and nylon

• Uniforms - Durable prints for jerseys and workwear

• Sportswear - High-quality prints for athletic gear

• Decor - Print on cushions and tablecloths

• Kids' Wear - Safe, Oeko-Tex-compliant prints

DTG vs. DTF vs. Toner Transfers

Need help choosing between methods? Here’s a quick comparison:

| DTF & DTG COMPARISON | ||||

|---|---|---|---|---|

| Method | Great for | Fabric Types | Pretreatment | Feels Like |

| DTG | Cotton apparel, soft feel | Cotton, cotton blends | Not necessary, but recommended. Pretreatment must always be used with white ink. | Soft, breathable |

| DTF | Versatility, fast output | Cotton, poly, blends | Not needed | Slightly thicker |

| Toner | Small-run, no cutting or weeding required | All colors/fabrics. Can also work on hard surface items. | Not needed | Smooth finish |